A new technique takes bioprinting — in which an ink of cells is printed, layer by layer, to form a structure — to a whole new, and icy level. Investigators from the Zhang lab at Brigham and Women’s Hospital have developed a technology that they term “cryobioprinting,” a method that uses a bioink embedded with cells to print frozen, complex structures that can be easily stored for later use. The team introduced cryobioprinting in a paper recently published in Matter and further described how to apply the technology to muscular tissue engineering in a paper just published in Advanced Materials.

A new technique takes bioprinting — in which an ink of cells is printed, layer by layer, to form a structure — to a whole new, and icy level. Investigators from the Zhang lab at Brigham and Women’s Hospital have developed a technology that they term “cryobioprinting,” a method that uses a bioink embedded with cells to print frozen, complex structures that can be easily stored for later use. The team introduced cryobioprinting in a paper recently published in Matter and further described how to apply the technology to muscular tissue engineering in a paper just published in Advanced Materials.

“Cryobioprinting can give bioprinted tissue an extended shelf life. We showed up to three months of storage, but it could be much longer,” said Y. Shrike Zhang, PhD, senior author of both papers and an associate bioengineer in the Brigham’s Department of Medicine. “And the unique variation, or what we call the vertical 3D cryobioprinting technique we’ve described, may have broad application in tissue engineering, regenerative medicine, drug discovery and personalized therapeutics.”

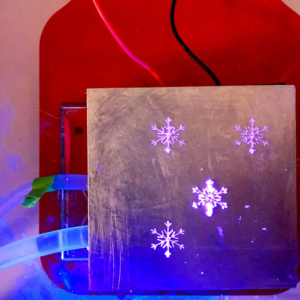

Zhang and colleagues used a cryoprotected bioink laden with cells to print tissue constructs on a customized freezing plate. The freezing plate allowed them to precisely control and stabilize temperature during the cryobioprinting procedure. These printed structures were immediately cryopreserved in a liquid nitrogen tank for later use. The team optimized and evaluated the technique, finding that it could faithfully fabricate tissue constructs that could potentially be used as implants and tissue products.

In Advanced Materials, Zhang and co-authors report on using the cryoprotected bioink to create vertical, 3D structures that mimic complex, delicate, and anisotropic tissues found in the human body. Many tissues in the body, including muscles and neurons, are anisotropic, meaning that they have properties that are different in different directions. The structures the researchers created were also anisotropic, with microscale pores aligned in the vertical direction. As a proof-of-concept, the team constructed a muscle-tendon unit using myoblasts (cells that can give rise to muscle cells) and fibroblasts (cells that produce structural frameworks in connective tissue). The team also fabricated a muscle-microvascular unit.

The researchers note that this work represents very early technological demonstrations and will still need extensive validation and tests before use in the clinic, but the two papers represent an important step forward.

“As the field of tissue engineering is growing fast, these fabricated tissue constructs may find a plethora of applications in muscular tissue engineering and beyond,” said Zhang.

Funding: The authors acknowledge support by the Brigham Research Institute. Work was also supported by the FRQNT’s International Internship Award (279390), MITACS Globalink Research Award (IT14553), McGill’s Graduate Mobility Award, McGill’s Doctoral Internship Award, the FRQNT’s Postdoctoral Fellowship (296447), Program of China Scholarship Council (No.201807045057), the High-Level Talent Internationalization Training Program of Henan Province (No.2019004), the National Institute on Deafness and other Communication Disorders (NIDCD) of the National Institutes of Health (NIH) grant numbers R01DC005788 and R01DC014461.

Papers cited:

Ravanbakhsh H et al. “Freeform Cell-Laden Cryobioprinting for Shelf-ready Tissue Fabrication and Storage” Matter DOI: /10.1016/j.matt.2021.11.020

Luo Z et al. “Support Bath-Free Vertical Extrusion Cryo(bio)printing for Anisotropic Tissue Manufacturing” Advanced Materials DOI: 10.1002/adma.202108931

Source: BRIGHAM AND WOMEN’S HOSPITAL