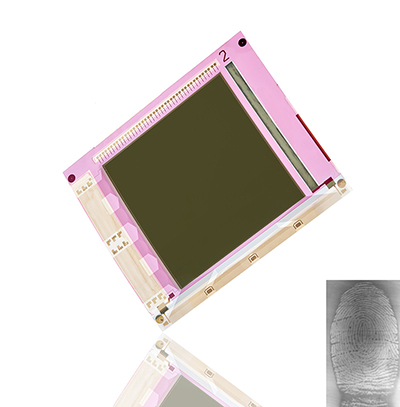

FlexEnable, the leader in the development and industrialization of flexible organic electronics, and ISORG, the pioneer in organic photo detectors and large area image sensors in printed electronics, have revealed the world’s first large area flexible fingerprint sensor on plastic designed for biometric applications. With an 8.6 cm x 8.6 cm active area, 84µm pitch (78µm pixel size with 6µm spacing) and 1024 x 1024 = 1048576 pixel resolution, this revolutionary flexible sensor is only 0.3 mm thick and can operate in visible and near infra-red up to wavelengths of 900 nm. The technology is capable of measuring not only the fingerprint, but also the configuration of veins in the fingers, providing additional security versus that of a surface fingerprint alone.

This new sensor breakthrough has been achieved by deposition of organic printed photodetectors (OPD), pioneered by ISORG, onto a plastic organic thin-film transistor (OTFT) backplane, developed by FlexEnable, to create a flexible fingerprint sensor that is ultra-thin, light, robust and lensless. The large label-thin sensing area can be applied to almost any surface – and even wrapped around the objects in our daily lives that we typically come into contact with – such as a car steering wheel that recognises the driver as soon as the wheel is touched, or a credit card with integrated biometric detection that does not compromise current form factors. The addition of vein sensing on top of fingerprint sensing provides a second level of security, since each user’s vein pattern in the finger is unique and requires the user to be alive for detection to be successful.

This new sensor breakthrough has been achieved by deposition of organic printed photodetectors (OPD), pioneered by ISORG, onto a plastic organic thin-film transistor (OTFT) backplane, developed by FlexEnable, to create a flexible fingerprint sensor that is ultra-thin, light, robust and lensless. The large label-thin sensing area can be applied to almost any surface – and even wrapped around the objects in our daily lives that we typically come into contact with – such as a car steering wheel that recognises the driver as soon as the wheel is touched, or a credit card with integrated biometric detection that does not compromise current form factors. The addition of vein sensing on top of fingerprint sensing provides a second level of security, since each user’s vein pattern in the finger is unique and requires the user to be alive for detection to be successful.

Large area fingerprint sensors allow more information to be collected – which directly provides better performance on two key metrics compared to smaller sensor areas – higher security and lower false rejection rate. However, large area fingerprint sensors become prohibitively expensive for many applications, when conventional silicon technology is used. In contrast, flexible plastic fingerprint sensors bring cost advantages to large area manufacturing due to the low temperature and printing process on plastic being employed. Moreover, fingerprint sensors made of plastic have similar optical performances to conventional optical fingerprint sensors such as sensitivity, linearity, and low noise, but without the need for expensive and bulky optics.

Chuck Milligan, CEO of FlexEnable, said: “FlexEnable’s ground-breaking flexible electronics technology in combination with ISORG’s unrivalled expertise in OPDs and large area image sensors brings game-changing capabilities for biometric detection that can be applied to almost any surface – anything from door handles to wrists. For example, imagine a mobile device whose surface or edges know who is holding or touching the device. Such capabilities are viable because of the flexibility, thinness, and much lower cost per unit area compared to silicon area sensors. “

Jean-Yves Gomez, CEO of ISORG, said: “This break-through development will spark the creation of next-generation products in biometrics. No other solution can offer large area sensing as well as finger print and veins recognition while being flexible, light and robust. Moreover, our team is able to provide reference design as well as image improvement algorithms and illumination solutions to ease the sensor integration into new applications.”

About FlexEnable

FlexEnable, based in Cambridge, UK, has developed the world’s first flexible transistor technology platform, the key to truly flexible and cost effective electronics over large and small surfaces. With over a decade of experience, IP development and technology awards, FlexEnable works together with customers to drive innovation across flexible sensors, smart systems and video-rate displays. FlexEnable’s technology platform enables new mobile and wearable products as well as sensor arrays and structural electronics that bring an extra dimension to the IoT (Internet of Things). Customers include OEMs, component manufacturers and materials suppliers. Information on our partnering offerings, ProductEnable™, MaterialsEnable™ and FabEnable™, can be found on www.flexenable.com.

About ISORG

ISORG is the leading and pioneer company in organic photodetectors and large area image sensors in printed electronics. ISORG develops a disruptive technology transforming plastic and glass into smart surfaces able to see. These new sensors are conformable, thin and lightweight with low current consumption, offering unique advantages over traditional image sensors in terms of sensing area, cost per area ratio and mechanical integration. These sensors enable creation of many innovative products such interactive surfaces for object detection and recognition, large area scanning surfaces, revolutionary user interfaces for consumer products. ISORG technology opens innovation for medical, industry and consumer markets, www.isorg.fr.

Source: FlexEnable